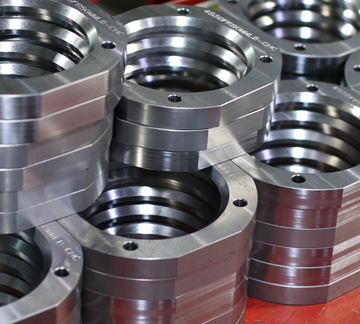

From simple to complex parts we provide accurate and precise milling of parts with vertical and horizontal machines. CEM will work with you to make prototypes, finish low run jobs, or meet demands for high volume needs.

Precision Vertical CNC Milling Services

At CEM Machining and Fabrication, our Vertical CNC Milling Machines deliver exceptional precision in shaping and fabricating a variety of materials, including metals, plastics, and composites. Our advanced vertical machining capabilities ensure high accuracy and efficiency for a wide range of applications.

Our Vertical CNC Machining Capabilities

We specialize in a variety of machining operations, including:

-

Face Milling – Producing smooth, flat surfaces with high precision.

-

Drilling – Creating holes of various depths and diameters for diverse applications.

-

Tapping – Forming internal threads inside pre-drilled holes.

-

Counterboring – Enlarging the opening of existing holes for fastener placement.

-

Pocketing – Cutting open or closed cavities into a workpiece.

-

Embossing – Adding raised patterns or textures to material surfaces.

-

Engraving – Etching detailed markings, logos, or designs into the material.

Our machining centers feature fully automated pallet changers, allowing for continuous machining while minimizing downtime. This enhances efficiency and productivity, ensuring the best results for our customers.

Focus Industries

We provide high-precision machining solutions for industries that demand accuracy, consistency, and reliability, including:

-

Food & Beverage

-

Construction

-

Life Science

-

General Industry

-

Logistics

-

Automotive

-

Electronics

At CEM Machining and Fabrication, we are committed to delivering superior CNC milling solutions tailored to the unique needs of our clients. Whether you require precision components, custom machining, or high-volume production, we have the technology and expertise to meet your demands.

Our Quality Pledge

We pledge to deliver products and services that meet or exceed customer requirements, uphold CEM’s high standards, and ensure exceptional safety, performance, and reliability.

Commitment To Quality Goal

To drive a culture of excellence by embedding quality, safety, and reliability into every process and product, ensuring that CEM consistently exceeds customer expectations and industry standards

Furthermore, CEM is deeply committed to client satisfaction and profitable operations, achieved through continual improvement and employee ownership of all programs and projects. We hold ourselves to ever-increasing standards of excellence in everything we do, recognizing that satisfying client requirements is crucial to our continued success and a key reason behind our high customer retention and repeat business.

Our processes are designed to begin by clearly defining the client’s requirements, followed by a thorough review to ensure that these requirements have been fully met. Importantly, everyone involved in providing products or services to our clients takes ownership of ensuring that the client’s needs are well-defined, well-documented, and that the final products or services fully meet the specified requirements.

Industry Specific Needs and Materials

As a trusted partner to customers large and small, we have become experts in working with materials used across our focus industries

| CNC Materials | |

|---|---|

| Metals | |

| Aluminum | |

| Copper | |

| Bronze | |

| Brass | |

| Steel (Stainless Steel) | |

| Plastics | |

| Delrin | |

| UHMW | |

| Micarta | |

| Nylon | |

| HDPE | |